Water is a scarce resource & is being used daily in Millions of litres for Domestic & Industrial Purposes. The effluent generated is discharged into Environment after treatment thereby not only wasting this precious natural resource but also damages the eco-system as whole.

The effects of such effluents discharge without complete treatment pollutes the surface water, ground water, rivers, sea, etc causing irreversible ill effects on eco-system.

NIR Group is committed to its services to society for treatment of such effluents & leave behind a good natural environment for the future generation which we owe to them.

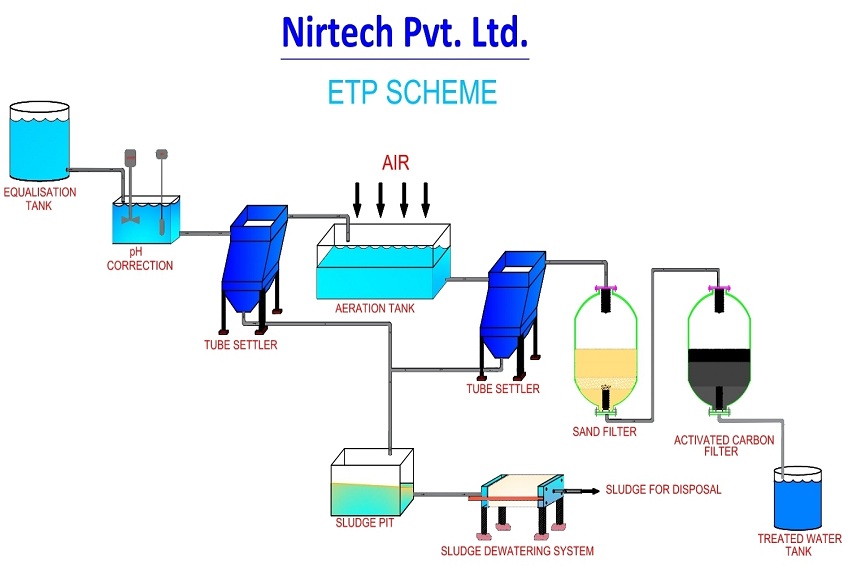

NIRTECH offers a wide range of waste water treatment plants, which are used for treating waste water in various industrial, commercial and domestic areas. We set up these treatment plants after proper assessment and end use / discharge needs of the specific industry. Our waste water treatment plants utilize chemical and biological processes. We provide the required equipment to perform high rate clarifier coagulation, precipitation and bio-media clarification of waste water. The treated water quality from offered effluent treatment plant meets the discharge requirement & at times can be reused for few applications.

Following are the general steps in ETP plant:

- Preliminary treatment

The objective of preliminary treatment is the removal of coarse solids and other large materials from effluent.

- Primary treatment

Primary treatment usually includes the removal of finer solids from the wastewater via chemical dosing and physical settling / filtration.

- Secondary treatment

Secondary treatment typically removes the COD/ BOD in the wastewater through the use of microbes, which utilize organics as an energy source.

- Tertiary and/or advanced treatment

Sodium Hypo Chloride / Ozonation are used to kill microbes & bacteria. Further Graded Sand Filter / activated glass media filter & Activated Carbon Filters are used to remove suspended solids, odour & colour from waste water.

Our treatment plants are highly effective for treating:

- Industrial waste

- Domestic sewage

- Canteen waste

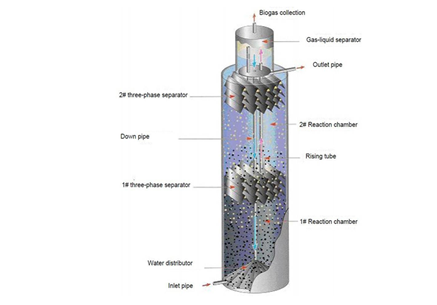

Condensate Polishing Unit

Generally the condensate from Sugar Industries / Molasses / Grain Based distilleries has high COD which needs to be treated so as to reuse the same. There are volatiles / low molecular organics in MEE condensate / Process Condensate / Spent leese. NPL shall provide cost effective solution based on Anaerobic / Aerobic/ Membrane Technology so as to reduce the TDS, COD, etc & offer reusable quality water

Effluent Treatment (ETP)

Design, engineering, supply, erection and commissioning of new ETP's

- Optimization of existing ETP system

- O & M services

- Effluent treatment feasibility studies

- Cost saving by using effective & modern methods of effluent treatment

- Waste Water Audits

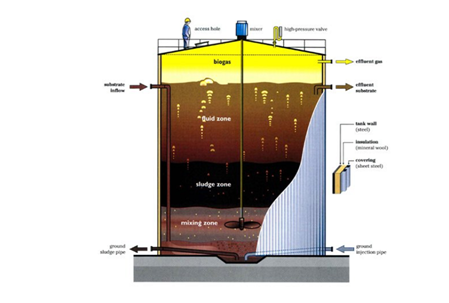

Attached is the Scheme for the ETP

|